The development of laser cleaning devices has replaced all traditional methods. The metal stripping process in various industries has several traditional methods that utilize chemical and mechanical techniques for cleaning.

The main issues with these methods include: negative environmental impact and wear on the cleaning objects. Sandblasting systems generate large amounts of waste and can damage underlying surfaces. Cleaning with chemical solvents produces vapors and potentially hazardous liquid waste. The lack of traditional cleaning methods that can increase the speed and quality of the cleaning process without these disadvantages has led to the advancement of modern technology in surface stripping. Additionally, as global environmental issues become more severe, the demand for clean industrial products and equipment in the global market increases year by year.

Laser technology has recently emerged as a new technology and has been shown to fully achieve these goals using laser cleaning devices, in addition to not having the aforementioned disadvantages, highlighting its superiority. Gradually, it is becoming a suitable alternative to traditional stripping with chemical substances and contact physical cleaning technology. It is slowly becoming the primary cleaning technology in the industrial sector.

Laser Cleaning Machine

The difference between continuous and pulsed laser cleaning machines

For large-scale, uniform taskslike derusting, a continuous fiber laseris the best choice due to its efficiency and cost-effectivenessFor precision and delicate cleaning taskssuch as tire mold cleaning, paint removal, or weld oxide layer removal, pulsed fiber lasers are preferred. Depending on the specific task, you may choose between multimode or single-mode pulse types for optimal results

Laser cleaning machine catalog

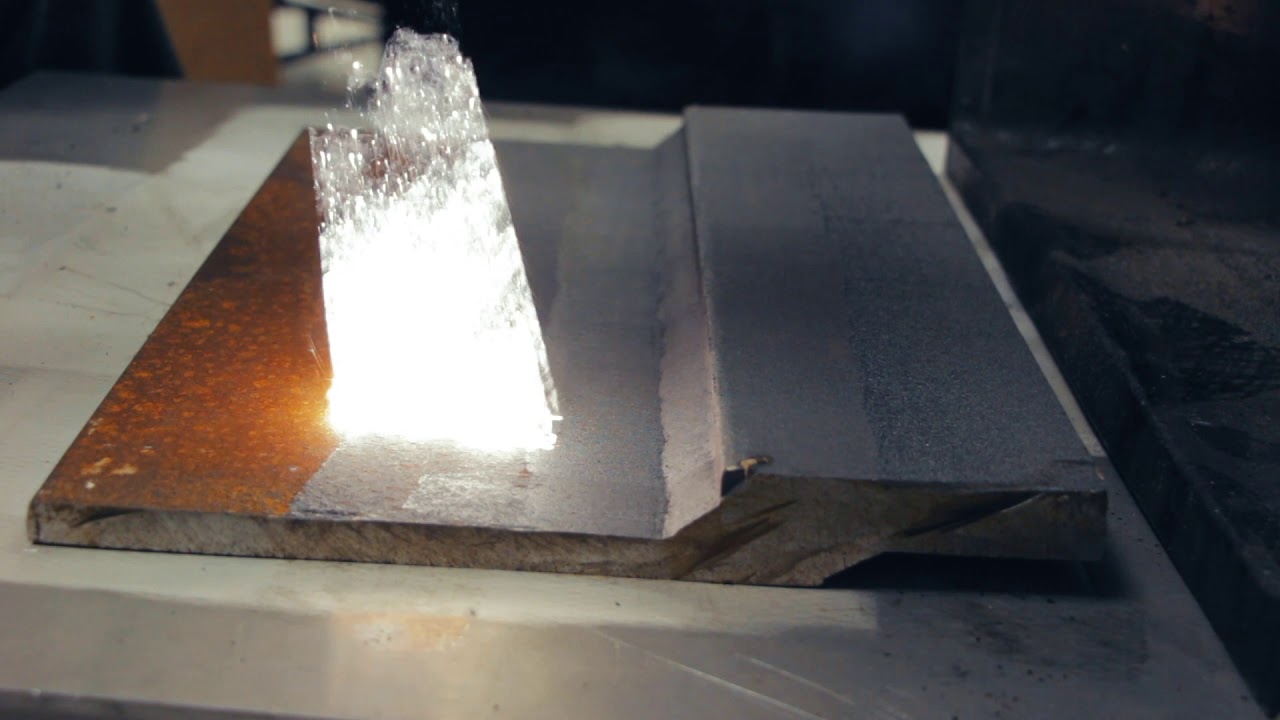

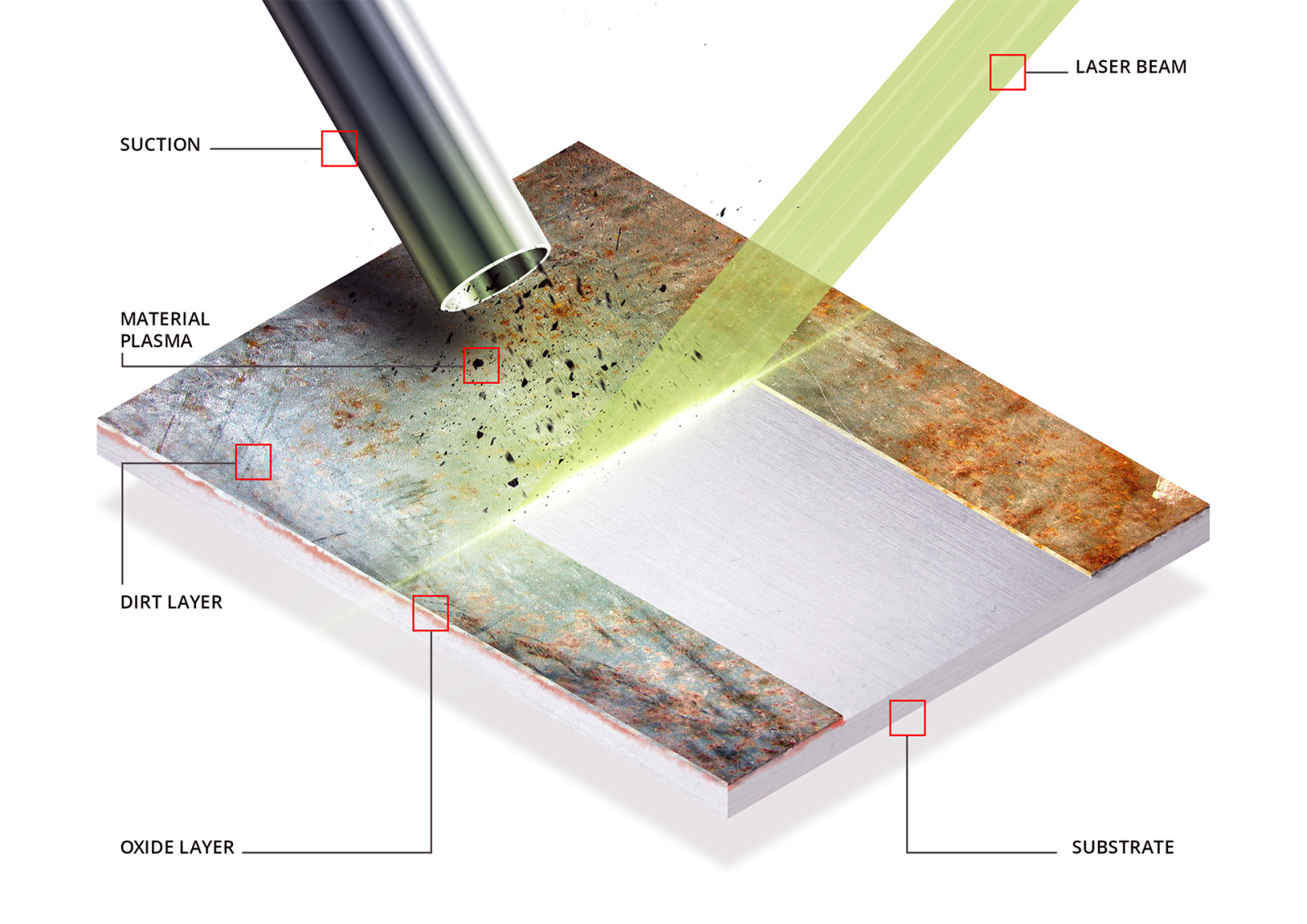

The laser can achieve a high concentration of energy in both time and space. A focused laser beam can generate temperatures of thousands or even tens of thousands of degrees near the focus, causing evaporation or instantaneous decomposition of dirt. Thus, it operates based on the photophysical reaction resulting from the interaction between the high-intensity laser beam and the layer of contamination, in such a way that the laser beam is absorbed by the layer of contamination while not being absorbed by the underlying materials.

Therefore, when the beam encounters the laser cleaning device, several events occur. Initially, due to the difference in absorption coefficients of the specific wavelength of laser energy between the substrate and the surface pollutants, as well as the differing expansion coefficients between the contaminants and substrates, the contaminants expand differently. When the expansion force of the contaminants exceeds the force of adhesion to the substrate, the dirt is detached from the surface of the object.

In another phenomenon, with higher energies, the contaminants are vaporized or plasma is formed at the energy focus point. The shock waves generated by the ionized gases of the micron plasma cause the contaminants to separate and enhance the cleaning effect on the surface. The shock waves from the laser beam itself also contribute to a more effective cleaning process, and their short pulse width prevents damage to the subsurface and heat buildup.

The infrared light emitted by the laser can be used to clean residual debris on metal surfaces, such as zinc oxide residues on steel, aluminum, stone, copper, and other substrates. Furthermore, the technology of the laser cleaning machine is one of the few cleaning technologies for industrial cleaning with robotic and automated arms, which reduces operational costs, improves the quality of metal mass removal, and meets market demands.

Price of laser metal cleaning machine

The Rust Removal Laser Machine or Laser Polishing and Cleaning Device of Vanda Ray Industry is designed to eliminate rust, corrosion, and metal coatings without the need for chemicals. It offers high effectiveness, is environmentally friendly, and is also suitable for cleaning paint, laser screws, laser welding, and surface stains. It is highly suitable for the shipbuilding, advanced machinery, and railway lines industries. To obtain the price of the surface cleaning laser machine from Vanda Company, please contact our sales experts.

Laser Cleaner and its Effective Materials

Using the laser cleaning device, the following contaminants can be easily and quickly removed from the surfaces of various components, especially automotive parts:

- Rust on metal components

- Oil and grease on components

- Oven paints and ordinary paints on metals and coatings

- Mud and dirt on components

- Dust on components

Advantages of Using Laser Cleaners in Various Industries

As laser cleaning devices offer numerous advantages, they have become the most effective method for removing unwanted materials from the surfaces of materials. Compared to traditional methods, the following advantages can be summarized for laser cleaning devices:

- Rust removal without direct contact with the surface

- Rust removal without consumables, operating solely on electricity

- Cost reduction of up to 84% compared to dry ice cleaning

- No surface damage during cleaning

- No maintenance costs

- Quick setup and ease of operation

- Various cleaning modes (spiral, uniform, etc.)

- High cleaning efficiency and time savings

- Reduced sensitivity to corrosion after cleaning

- Easy to automate

- Environmentally friendly, with no use of chemicals, solvents, or waste production

- Low noise

- Uniform cleaning with controllable cleaning areas

| Model | LCI-1000 | LCI-1500 | LCI-2000 |

|---|---|---|---|

| Laser Power | 1000W | 1500W | 2000W |

| Power Consumption | 4KW | 5.5KW | 7KW |

| Laser Wavelength | 1080 | ||

| Beam Quality | less than 1.3 | ||

| Laser Source | Fiber | ||

| Laser Output Type | Continuous | ||

| Pulse Frequency | 1-4000HZ | ||

| Device Dimensions | 1100mm*990mm*650mm | ||

| Device Weight | 220KG | ||

Laser cleaning machine (cleaning grease from parts)

Laser Cleaning Machine

Comparison between different cleaning methods and cleaning with a laser cleaning machine

| Cleaning Method | Laser | Chemical | Mechanical | Dry Ice | Ultrasonic |

|---|---|---|---|---|---|

| Features | No contact with surface | Contact with surface | Mechanical sanding | No contact with surface | Contact with surface |

| Damage | No | Yes | Yes | No | No |

| Efficiency | High | Low | Low | Medium | Medium |

| Consumables | Electrical | Chemical substance | Abrasive paper and grinding wheel | Dry ice | Chemical substance |

| Effect | Excellent | Regular and irregular | Regular and irregular | Good but irregular | Good but narrow |

| Precision | High | Low | Medium | Uncontrollable | Uncontrollable |

| Environmental Safety | Non-polluting | Chemical pollution | Environmental pollution | Non-polluting | Non-polluting |

| Operation | Easy - Manual or Automatic | Complex - Requires specifications | Complex - Environmental protection required | Easy - Manual or Automatic | Easy - Consumables need to be added |

| Cost | High initial cost - No consumables | Low cost - High consumption | High initial cost - High maintenance and operation | Medium cost - High consumption | Low initial cost - Medium consumption |

Laser Cleaning Devices and Their Applications in Various Industries

- Removal of rust from drilling pipes using a laser cleaner.

- Cleaning of rubber injection molds and molds used in tire and automobile rubber production using a laser cleaner.

- Cleaning of molds used in the food industry with a laser cleaner.

- Removal of old paint from airplanes using a laser cleaner for new coating.

- Removal of rust from weapons and cleaning of related equipment.

- Cleaning of the exterior walls of buildings with a laser cleaner.

- Efficient cleaning of stone statues and historical artifacts.

- Oxide removal from components prior to soldering in the electronics industry.

- Remote cleaning of pipes in nuclear power plants for worker safety.

- Removal of oil contamination from precision machinery in various industries.

- Surface finishing and rust removal in the steel industry.