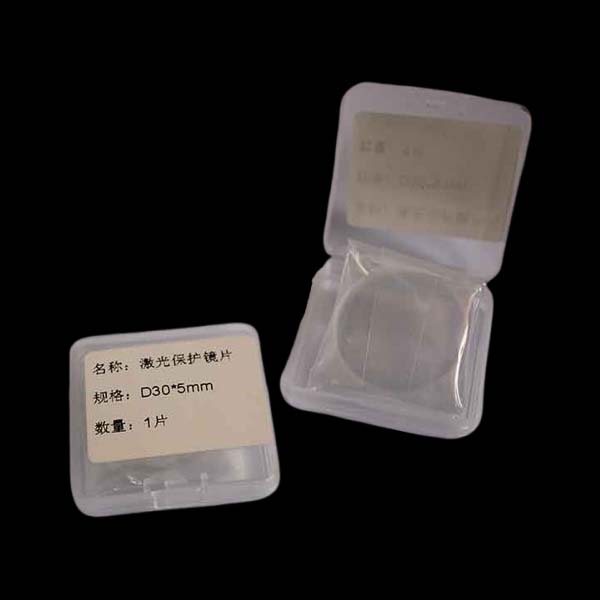

Protective glass of the laser welding machine

Laser Welding Glasses

Laser welding glasses are essential for protecting the eyes from the harmful rays emitted during the laser welding process. These glasses are specifically designed to filter out harmful wavelengths of light, ensuring safety for workers in environments where high-intensity lasers are used. They are crucial for preventing eye damage, especially from the intense light and heat generated during laser welding operations.

Best Laser Welding Glasses

The best laser welding glasses are those that provide optimal protection while maintaining comfort and clarity of vision. These glasses are typically equipped with high-quality lenses that can block specific wavelengths of laser light, such as infrared or ultraviolet, depending on the type of laser being used. They should also be lightweight, durable, and have adjustable features to accommodate different facial structures. When selecting the best glasses, it’s important to consider factors like the laser’s wavelength and the intensity of the light exposure.

Fiber Laser Welding Glasses

Fiber laser welding glasses are tailored for use with fiber lasers, which are known for their high precision and intensity. These glasses feature special coatings or filters that block the specific wavelengths of light emitted by fiber lasers, such as 1070 nm, 1080 nm, or others in the infrared range. Due to the concentrated power of fiber lasers, these glasses are particularly designed to offer strong protection while ensuring that the operator has clear visibility of the workpiece during the welding process.

Protective Glasses for Laser Welding

Protective glasses for laser welding are a vital piece of safety equipment for anyone involved in laser welding. These glasses are made to shield the eyes from the intense light produced during the welding process, which can include harmful ultraviolet (UV) and infrared (IR) radiation. They come in a variety of styles and lenses, ensuring a snug fit and comfort for long working hours. The protective lenses are typically darkened or specially coated to provide the necessary optical filtering to prevent eye strain and injury.

Laser Safety Glasses Blue

Laser safety glasses with blue lenses are designed to protect the eyes from specific types of lasers, particularly those that emit light in the blue or violet spectrum. These glasses are specially engineered to block harmful wavelengths while still allowing the user to see through them clearly. The blue-tinted lenses also reduce glare, providing additional comfort when working with lasers. These glasses are ideal for environments where blue or violet lasers are being used for precision tasks.

Laser Welding Goggles

Laser welding goggles are similar to laser welding glasses, but they offer more coverage and a tighter fit around the eyes. These goggles are designed to provide a higher level of protection against the intense light from lasers. They are particularly useful in situations where a worker is exposed to higher levels of laser radiation or where the laser is used at close proximity. These goggles ensure that no harmful laser radiation can reach the eyes, and their design helps prevent stray light from entering around the sides.

Laser Safety Eye Glasses

Laser safety eye glasses are a critical part of personal protective equipment (PPE) for workers in environments where lasers are present. These glasses are engineered to filter out specific wavelengths of laser light, ensuring that the eyes are protected from potential damage caused by prolonged exposure. Laser safety eye glasses come in various styles, including prescription options, and are rated based on the laser class and the specific wavelengths of light they block. They are designed to be comfortable, effective, and durable for long-term use in industrial and laboratory settings.