Laser device chiller

Laser Device Chiller

A laser device chiller is a cooling system used to maintain the optimal temperature of the laser device during operation. Lasers generate heat during use, and excessive heat can damage the components and reduce performance. A laser device chiller helps dissipate this heat by circulating coolant through the laser’s cooling system, ensuring stable performance and preventing overheating. These chillers are commonly used in industries where lasers are employed for precise tasks such as cutting, engraving, or medical applications.

Laser Machine Chiller Price

The price of a laser machine chiller varies depending on factors such as its cooling capacity, brand, and features. Generally, a basic laser machine chiller can cost a few thousand dollars, while more advanced models with higher cooling power and additional features like remote monitoring or energy-saving capabilities can cost significantly more. The price is also influenced by the type of laser machine (e.g., fiber laser, CO2 laser) and the specific needs of the application. It’s essential to choose a chiller that matches the power and requirements of the laser system to ensure efficient cooling.

Fiber Laser Chiller

A fiber laser chiller is a specialized cooling unit designed specifically for fiber lasers. Fiber lasers are powerful and generate significant heat during operation, requiring precise cooling to maintain performance and extend their lifespan. A fiber laser chiller circulates coolant through the laser’s cooling system, regulating the temperature and preventing thermal damage. These chillers are typically designed to support the high power output of fiber lasers and are an essential component for industries that rely on fiber laser systems for cutting, welding, and marking.

Laser Chiller Coolant

Laser chiller coolant is a specially formulated liquid used in the cooling system of laser devices. It absorbs the heat generated by the laser and circulates it through the chiller to be dissipated. The coolant helps maintain the laser’s optimal operating temperature, ensuring consistent performance. Laser chiller coolants are typically designed to have a high thermal conductivity to efficiently absorb heat and prevent overheating. They also often contain anti-corrosive additives to protect the internal components of the cooling system and ensure long-term reliability.

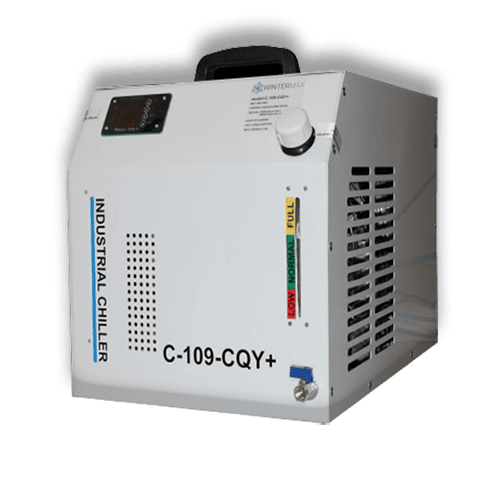

Industrial Laser Chiller

An industrial laser chiller is a high-performance cooling system designed for large-scale industrial applications that use laser systems. These chillers are built to handle the intense heat output from industrial-grade lasers, which are used in heavy-duty tasks like cutting, welding, or engraving. Industrial laser chillers are often more robust than smaller systems, with higher cooling capacities and features such as redundant components, remote monitoring, and customizable temperature settings. They are crucial for ensuring the efficiency and longevity of laser machines in industrial environments.

Laser Machine Water Chiller

A laser machine water chiller is a type of cooling system that uses water as a coolant to regulate the temperature of the laser system. Water chillers are an effective solution for cooling lasers in various applications, including fiber lasers, CO2 lasers, and other industrial laser machines. These water chillers typically consist of a tank of water, a pump to circulate it through the system, and a heat exchanger to dissipate the absorbed heat. Water chillers are efficient and cost-effective, offering a reliable solution for keeping laser machines at their ideal operating temperature.