Rotary laser welding machine

Single Motor and Dual Motor Rotary Systems: Differences and Applications

A rotary device is used to rotate workpieces in the welding process. These devices have different features and applications depending on the number of motors and their specific uses.

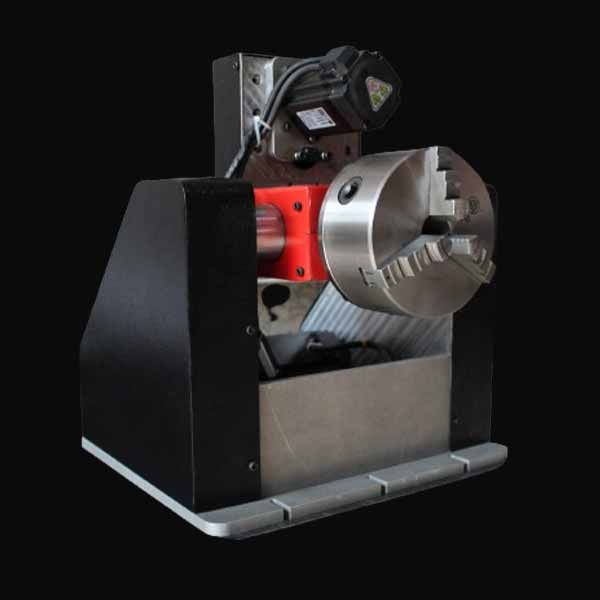

Single Motor Rotary

- Function: Used solely for manually rotating the chuck and workpiece.

- Application: Suitable for simple manual welding that does not require precise or complex control.

Single Motor Rotary Models from the Company Vanda:

- Single Motor Rotary with Gearbox and Chuck D=130

- Single Motor Rotary with Gearbox D=100

- Single Motor Rotary with Gearbox and Chuck D=160

- Single Motor Rotary with Pneumatic Gearbox

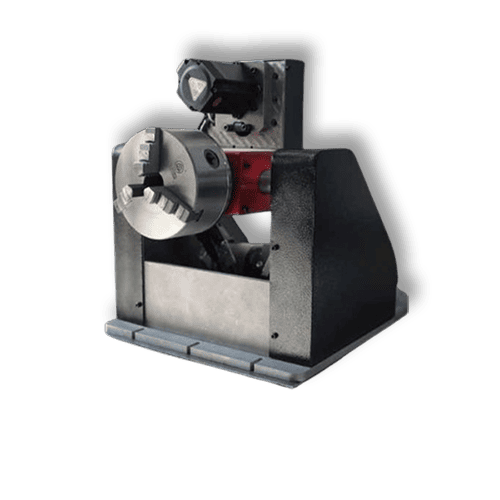

Dual Motor Rotary

- Function: In addition to rotating the chuck, a second motor is used for rotating the workpiece itself.

- Advantages:

- Angle Adjustment of Parts: This feature allows for welding various shaped pieces (including polygonal and round parts).

- More Precise Control: Using a CNC board allows for automatic and highly accurate control of rotary movement.

- Applications:

- Automatic Welding: Used in industrial production lines for high-precision welding of parts.

- Welding Complex Parts: Suitable for welding pieces that require simultaneous rotation on two axes (such as bowls, pipes, spheres, etc.).

Industries of Application:

- Home Appliances: Welding sinks

- Refineries: Welding spheres inside valves and pipes

- Metal Industries: Welding pipes, sheets, and other round components

General Applications of Rotary Systems:

- Polygonal Parts: Cubes, squares

- Round Parts: Bowls, pipes, spheres

- Various Industries: Home appliances, refineries, metal industries

Dual motor rotary systems offer greater flexibility and precision for welding various components compared to single motor rotary systems. The choice of rotary type depends on the workpiece, required accuracy, and type of welding needed.