Laser Welding Machine and Laser Welding

With the rapid advancement of laser technology, the production of devices and equipment that utilize this technology has expanded to facilitate work. One of these devices is the laser welding machine and laser welding technology. The high density of laser light can heat surfaces to the melting point within a few milliseconds, resulting in vaporization. This phenomenon is suitable for processes such as laser drilling and laser cutting. For lower laser powers, the surface temperature reaches the boiling point after a few milliseconds. Before vaporization, the temperature of the underlying layers reaches the melting point, allowing for good laser welding between surfaces with fiber laser welding machines.

With the growing trend of laser welding technology, significant advancements have occurred in this industry, leading to the development of laser welding machines or laser welding motors. Depending on the type of laser they use, these machines can be categorized as follows:

- Nd:YAG Laser Welding

- Fiber Laser Welding Machine

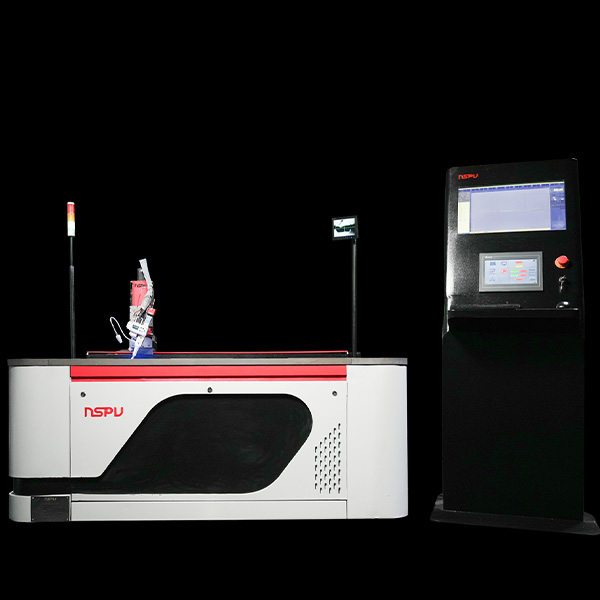

Manual laser welding machine

Manual laser welding machine

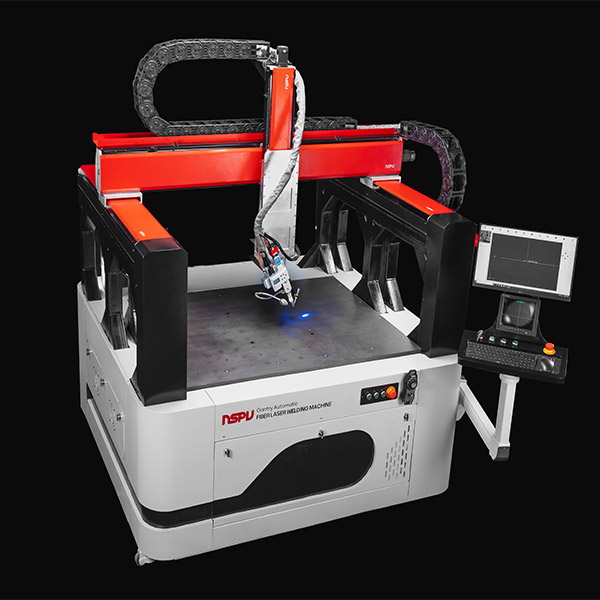

4 Axis Automatic laser welding machine

Fiber lasers are one type of solid-state lasers that, unlike gas and liquid lasers, produce the laser beam using small particles contained within the fiber. In this technology, the initial light for stimulating these small particles is generated by a diode laser. Due to the technology embedded in the optical fiber, similar to mirrors found in other types of lasers, the light is amplified through multiple reflections. The generated light is emitted at a wavelength of 1064 nanometers. This type of laser is used for its ease of light transmission and portability.

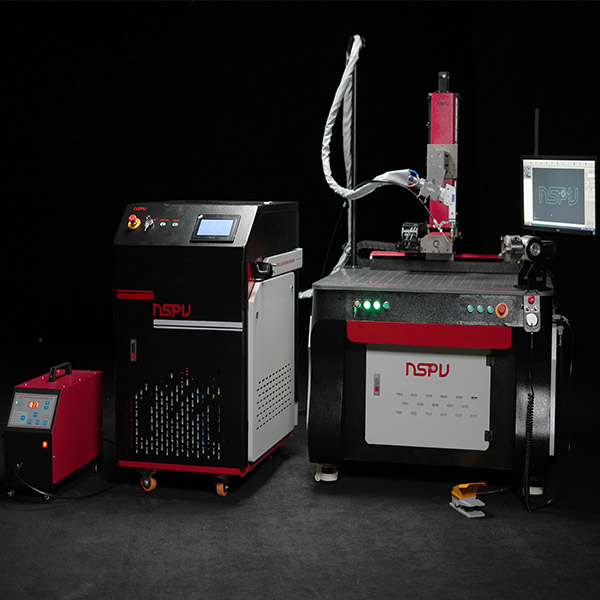

Buying a laser welding machine and its types

When purchasing fiber laser devices, it is important to consider that laser cleaning machines, welding machines, and small laser cutting machines can be categorized based on the type of lasers used in them, into continuous and pulsed types, according to their application. Fiber lasers are available in multimode and single-mode varieties based on the quality of the output beam.

In comparison to Nd:YAG welding, fiber laser welding machines require less equipment and materials, resulting in a smaller cabinet size. Because light is transmitted through the fiber, it offers greater flexibility for the user. As a result, working with fiber lasers is easier, leading to stronger weld connections, reduced weld defects, and, consequently, better weld quality.

Video on how to perform laser welding and various applications Fiber laser welding machine

Laser Welding of Aluminum Sheet Profiles

Comparison of fiber laser welding machine with CO2 welding machine

- Deep and narrow welds that are very clean and orderly, reducing the need for grinding or sanding after welding.

- Laser welding of two metals without the use of filler materials using a laser welding machine.

- Welding of two metals of the same type or two different types.

- Laser welding speed is 2 to 10 times faster than CO2 welding machines, resulting in increased production efficiency and economic savings (2 meters per minute with a penetration depth of 2 millimeters at 2 kilowatts).

- Minimal deformation and distortion with fiber laser welding due to heat, which is up to 200 times less than arc welding.

- Rapid cooling of the welded area and formation of a well-structured and strong joint after welding.

- High weld quality and flatness of the welded area, without porosity or dryness in the weld zone.

- Weld strength comparable to or even exceeding that of the base metal.

- Longer lifespan of the weld area compared to welds from CO2 arc welding and argon welding.

- Operating this machine is very easy, and training to use it is straightforward (comparison of laser welding machines with traditional welding (MIG, TIG welding)).

- Capable of automation and robotic welding for spot, linear, and perimeter laser welding with high speed and precision.

- Adjustable parameters of the fiber laser welding machine according to different materials to achieve the best weld quality.

- Long lifespan of the laser welding machine in high-volume production compared to traditional welding.

- Less environmental pollution.

- No discoloration or marks left on the backside of the workpiece.

- Laser welding of thin sheets, even thinner than 0.3 millimeters.

- Laser welding of miniature and small parts with high precision.

- Up to 80% reduction in electrical energy consumption during laser welding compared to CO2 welding machines.

- 70% reduction in finishing and grinding operations after laser welding.

- Laser welding can be performed under specific conditions in electromagnetic fields, vacuum, in the presence of specific gases, and under transparent materials.

- Clean welds without impurities.

- Unlike traditional welding, laser welding easily welds hard-to-reach parts.

Application of laser welding in various industries

Given the mentioned features of the laser welding machine and the development of fiber lasers, this device is increasingly used in various industries and has become essential equipment in these sectors. The applications of laser welding machines include:

- Laser machines for automotive parts

- Laser machines for the oil and gas industry

- Laser machines for household appliances

- Laser machines for kitchen products

- Laser machines for pipes, fittings, and sanitary equipment

- Laser machines for tank production

- Laser machines for battery manufacturing

- Laser machines for medical equipment

- Laser machines for mold making

- Laser machines for motor manufacturing

- Jewelry and gold

- Elevator manufacturing

- Cabinet and shelving construction

- Electronics industry

Reasons to save money with laser welding

- Reduced production costs due to the absence of consumables for laser welding.

- Increased production efficiency due to the high speed of the fiber laser welding machine, saving time and costs.

- Significant reduction in grinding costs after laser welding due to clean and strong welds produced by the machine.

- Noticeable decrease in electricity consumption costs and overall production costs with the fiber laser welding machine.

- No need to hire skilled labor due to the simplicity of the laser welding process.

How does a fiber laser welding machine work?

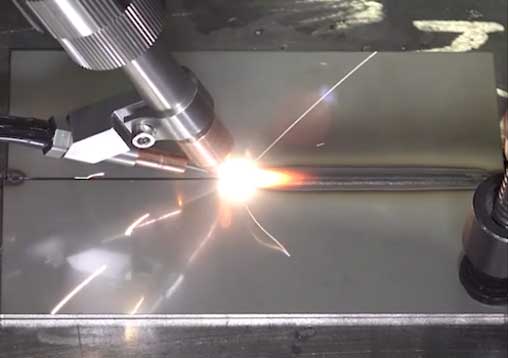

In a laser welding machine, the laser head is part of the laser welding assembly. The process is contactless and pressure-free, occurring as a result of direct laser light irradiation on the surface. Thanks to this laser technology, this machine can be used even in difficult locations where traditional welding is not feasible. By easily installing different nozzles on the welding assembly, laser welding can be performed at any angle on complex and large parts with irregular shapes. For safety, the laser welding assembly will only operate when the tip is in contact with the metal. The thermal sensors in the laser welding assembly can detect body heat.

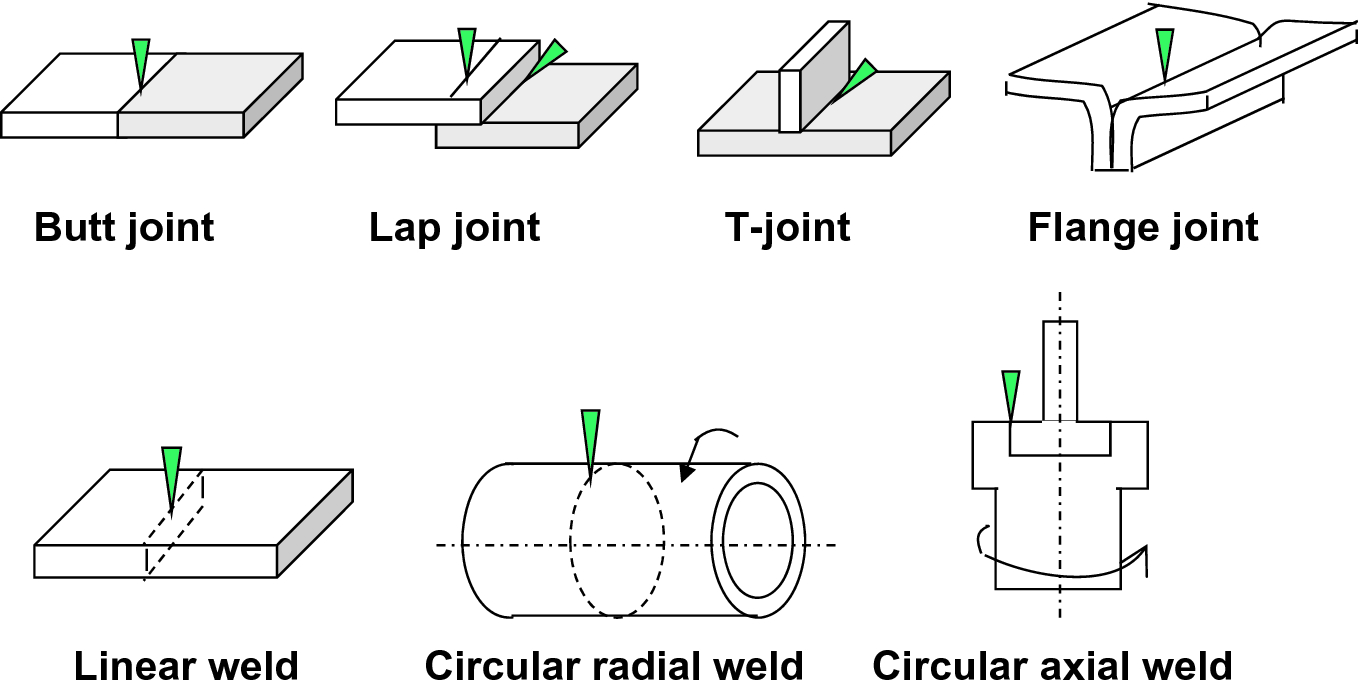

The types of welds that can be performed using this machine include:

- Spot weld

- Butt weld

- Stitch weld

- Seal weld

- Groove weld

- Flat fillet weld

- Internal fillet weld

- External fillet laser weld

- Laser weld for overlap

Types of laser welding

Materials that can be welded with a laser welding machine

The materials that can be welded using a laser welding machine include:

- Carbon steel

- Stainless steel

- Alloy steel

- Galvanized steel

- Aluminum and its alloys

- Titanium alloys

- Copper

- Nickel

- Certain plastics and composites

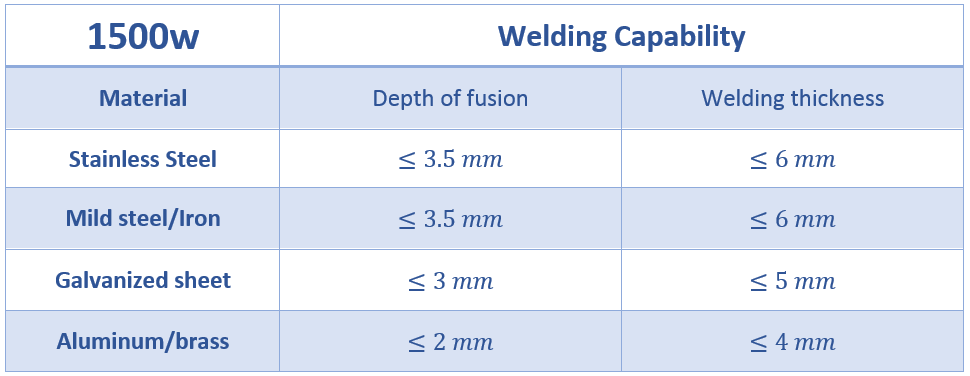

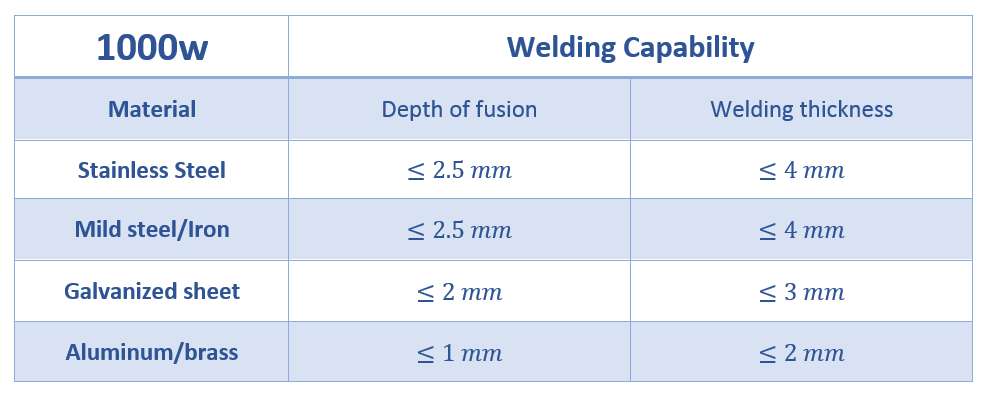

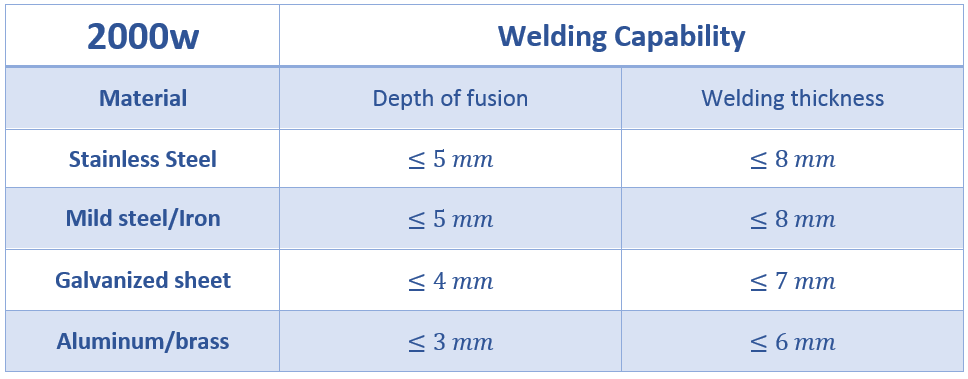

What power of a handheld laser welding machine welds what thickness of sheet?

Based on the laser power used in laser welding machines, the thickness of the various sheets that can be welded is shown in the image below. The penetration depth of the weld for each power level and material type is also displayed. You can choose your laser welding machine based on the important parameters provided.

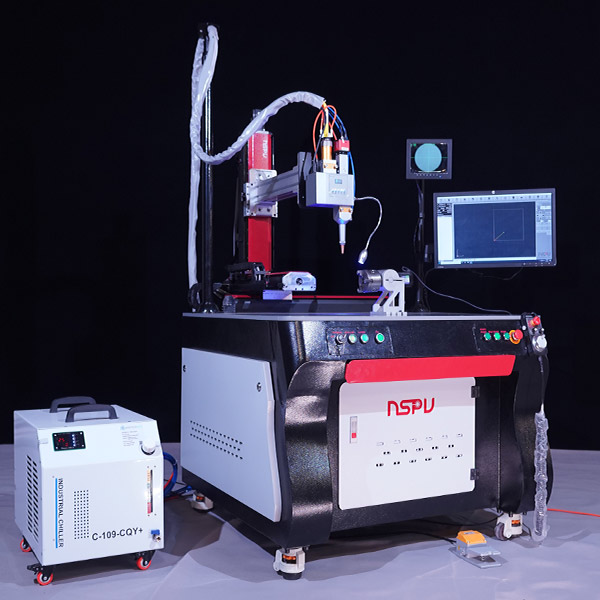

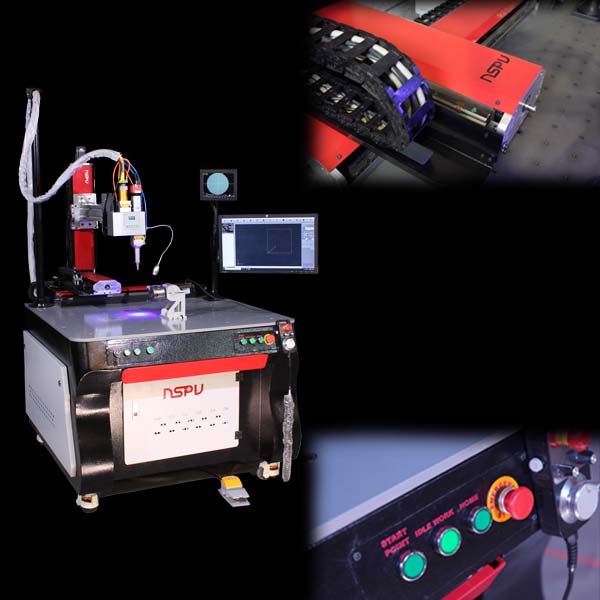

4 Axis Automatic laser welding machine

| Model | VALW-4A-1000 | VALW-4A-1500 | VALW-4A-2000 | VALW-4A-3000 |

|---|---|---|---|---|

| Laser Power | 1000W | 1500W | 2000W | 3000W |

| Power Consumption | 4KW | 5.5KW | 7KW | 8KW |

| Laser Source | Fiber Laser | |||

| Laser Wavelength | 1080nm | |||

| Beam Quality | M2 Less than 1.3 | |||

| Laser Mode | Continuous | |||

| Pulse Frequency | 1-50000Hz | |||

| Power Adjustment Capability | 0 to 100% | |||

| Weld Spot Diameter | 0.2-5mm | |||

| Focal Distance | 200/300mm | |||

| Weld Position Adjustment | With red light indicator | |||

| Weld Position Display | Display of weld position via camera | |||

| Cooling System | Water-cooled chiller | |||

| Welding Head | QILIN dual motor welding head | |||

| Welding Speed | Up to 150mm/s | |||

| Positional Accuracy on Axes | 0.01mm | |||

| Linear Motion Axes | x=500mm, y=400mm, z=300mm | |||

| Rotational Motion Axes | A=360° | |||

| Power Supply | AC380 | AC380V | AC220V 50/60Hz | |

Features and technical specifications of automatic laser welding machine

- High welding speed

- Simple operation and quick learning

- Robotic control for precise welding processes on complex and delicate parts that are very difficult to perform by hand

- Increased efficiency of the laser welding process in terms of speed, accuracy, and finesse compared to manual processes

- Real-time display of control parameters during the welding process to monitor and achieve optimal welding results

- Four-axis control system for easy programming of precise welding

- Easy welding of hard-to-reach parts

- Equipped with a CCD system and real-time monitoring display for precise and delicate welding processes

- High-precision welding of miniature and small parts

By combining the laser welding machine with a CNC system, it is easy to weld parts that require fine and precise welding, which is difficult to achieve using manual laser welding. This is provided that you adhere to the important and essential parameters of the automatic laser welding machine to ensure high-quality welds.

Applications of automatic fiber laser welding machine

Automotive industries: Welding of cylinder head gaskets, hydraulic seals, spark plugs, filters and batteries

Glass manufacturing industries: Welding of steel, stainless steel and titanium molds

Electronic industries: Welding of solid state relays, batteries, engine housings and systems, connections with fiber connectors

Home appliance industries: Welding of kitchen utensils and handles

Sanitary industries: Water pipes, tees, valves and showers

Home Laser Welding Machine

Air-cooled home laser welding machines usually use ambient air to cool their operation. This cooling method is less complicated than liquid systems and does not require piping or fluids. The smallest air-cooled laser welding machine is suitable for workshops and home environments, small and newly started industries due to its single-phase nature and welding of the thinnest thickness of metal parts.

Contact us to get a price for a home laser welding machine.

| Laser Power | 700 | 1200 | 1500 |

|---|---|---|---|

| Weld Thickness Range | 0.5mm-3mm | 0.5mm-3mm | 0.5mm-7mm |

| Weight | 21kg | 42kg | 58kg |

| Cooling System | Air Cooling | ||

| Fiber Length | 5m/10m | ||

| Laser Wavelength | 1060-1080nm | ||

| Welding Speed | 0-120mm/s | ||

| Type of Laser | Continuous/Pulsed | ||

| Material Types | Steel, Aluminum, Galvanized, Brass, Copper | ||

Contact us to get a price for a small air-cooled laser welding machine.

Currently, a handheld laser welding machine with dimensions of approximately 1 cubic meter in various powers for welding various types of metals such as steel, iron, galvanized steel, and aluminum is being produced at Novin Sanat Parto Gostar Vanda Company.

Portable home laser welding machine called air-cooled laser welding machine. Contact us for a price.

You can leave your information in the site’s online chat, social networks, and on the contact us page so that our sales consultants can contact you and contact us directly.