Laser machine head

laser machine head

A laser machine head is the central module that directs and focuses the laser beam onto the workpiece. It contains the optical and mechanical components responsible for shaping, focusing, and positioning the beam with high precision. Inside the head, you’ll find key elements such as the collimating and focusing lenses, beam alignment mirrors, sensors, and nozzle assemblies. Modern laser heads integrate autofocus systems and capacitive height sensors to maintain a consistent standoff distance during cutting or engraving. The head’s design directly affects beam quality, processing speed, and cut accuracy.

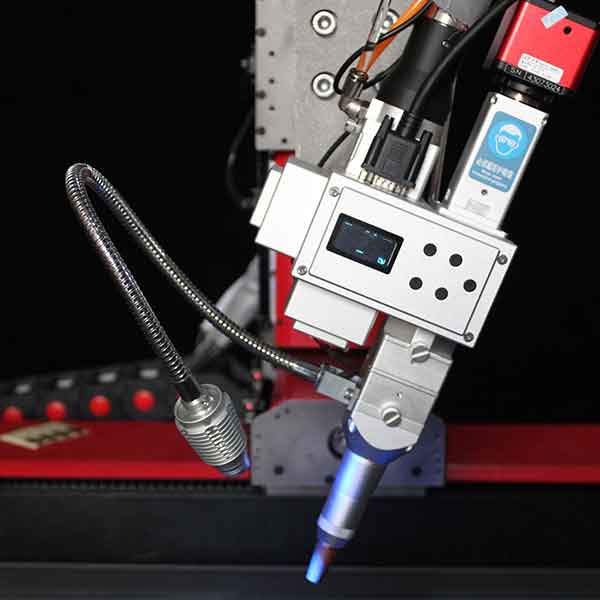

fiber laser machine head

A fiber laser machine head is optimized for the wavelength range of 1030–1080 nm and built to handle high power levels from fiber laser sources. These heads feature thermally stable optics, precise focusing modules, and efficient cooling to ensure consistent performance in cutting, welding, or marking applications. They’re typically used with fiber sources from brands like Raycus, IPG, or MAX. The modular design allows quick replacement of lenses and nozzles while minimizing alignment errors. High-end versions also include real-time focus tracking and anti-collision protection.

laser machine head price

The price of a laser machine head depends on several factors:

-

Type of process: Cutting, welding, cleaning, or marking heads have different designs and thermal loads.

-

Power rating: Heads rated for high power (6–20 kW) cost more due to better cooling and reinforced optics.

-

Sensor technology: Autofocus heads with capacitive height control or real-time monitoring are more expensive than manual-focus types.

-

Brand and compatibility: Heads made for popular systems like Precitec, Raytools, or WSX are priced higher due to precision engineering and support.

-

Cooling system and build quality: Water-cooled heads with advanced sealing and anti-spatter features generally cost more.

laser cutting machine head

A laser cutting machine head is designed to precisely focus the beam for material separation. These heads must combine stability, thermal resistance, and sensitivity to height changes. Autofocus functions automatically adjust the focal position according to material thickness. Nozzle geometry is also essential—it determines gas flow dynamics and cutting edge quality. For thick plate cutting, multi-layer heads with efficient water cooling are standard. In high-speed fiber laser cutting, lightweight heads reduce inertia, allowing faster and smoother motion on gantry systems.

laser cutting machine head price

The price of a laser cutting head is influenced by:

-

Focal length and optics quality: High-end fused silica lenses with low-loss coatings cost more.

-

Autofocus capability: Automatic heads add cost but improve productivity.

-

Cooling system: Water-cooled heads designed for 6–20 kW lasers are significantly more expensive than air-cooled versions.

-

Brand and service: Premium European and Japanese brands typically command higher prices due to quality and precision.

-

Sensor system: Capacitive or optical height sensors for accurate standoff control increase the overall price.

Budget-friendly models are available for low- to mid-power systems, while advanced industrial heads are an investment for production-level machines.

single head laser cutting machine

A single-head laser cutting machine is the most common configuration, featuring one precision laser head for all operations. It offers simpler setup, easier maintenance, and higher stability for complex geometries. Single-head systems are preferred when accuracy and flexibility are more important than speed. They can be equipped with autofocus, real-time monitoring, and intelligent gas control systems for superior cutting quality on a wide range of materials—from thin stainless steel to thick carbon steel plates.

double head laser cutting machine

A double-head laser cutting machine is designed for large-volume production. The two heads can either cut identical shapes simultaneously or perform complementary tasks on one workpiece. The benefit is significantly higher throughput and reduced idle time. The system usually includes dual servo drives, beam splitters, or independent laser sources to maintain equal performance on both sides. However, proper synchronization and calibration are essential to prevent dimensional deviation. Industries producing decorative panels, advertising boards, and fabric patterns often choose this configuration for efficiency.

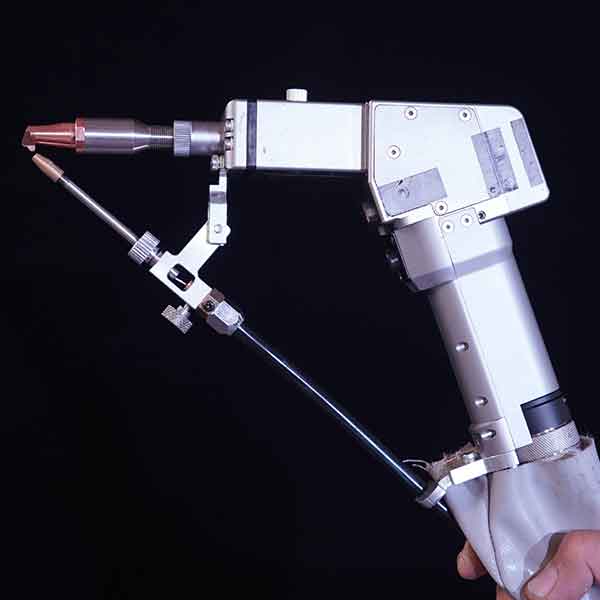

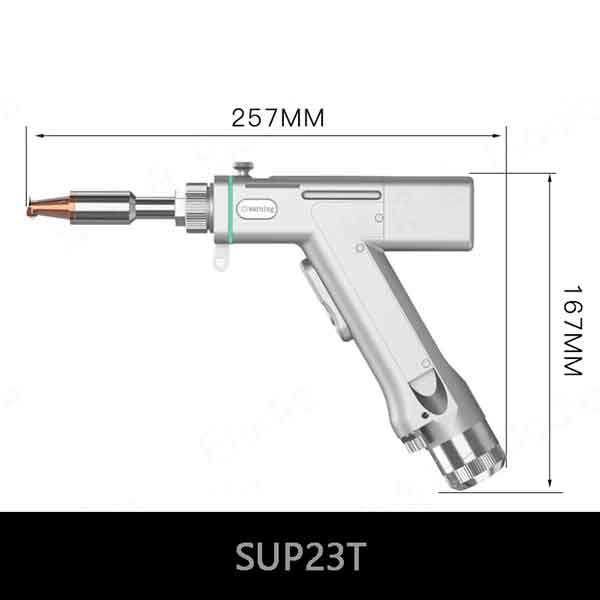

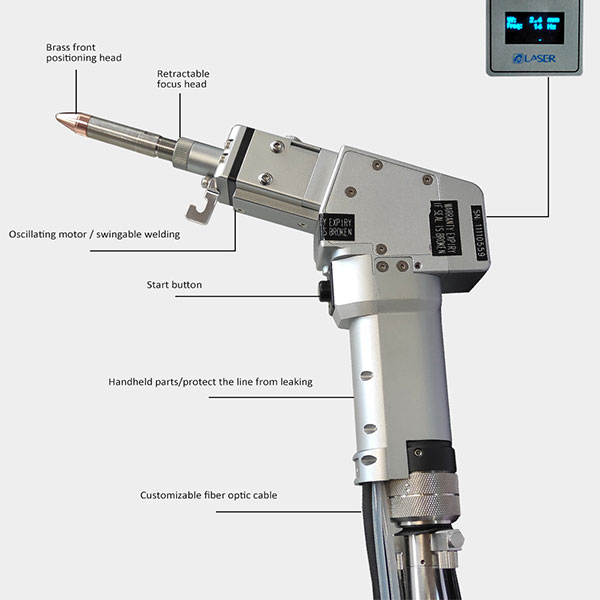

laser cleaning machine head

A laser cleaning machine head delivers short laser pulses to remove rust, paint, or contaminants from surfaces without damaging the base material. These heads are designed for high repetition-rate pulsed fiber lasers and often integrate a scanning mirror (galvo) and interchangeable optics for different spot sizes. They are lightweight for handheld operation and have protective housings against dust and reflection. Some advanced models also include suction ports for fume extraction. Laser cleaning heads are widely used in automotive, mold maintenance, and surface treatment industries.