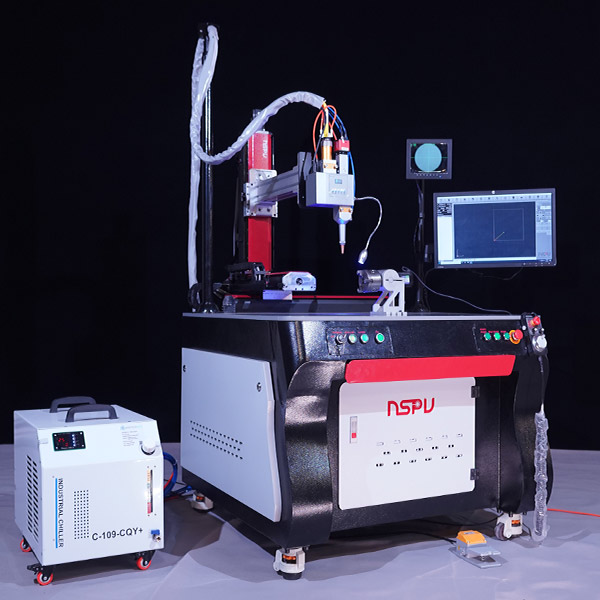

Manual laser welding machine

ویژگی های محصول

- The laser welding machine can easily weld long distances by directly applying a laser beam to the surface and melting it, without leaving any black marks on the back of the weld. At the same time, it achieves a significant melting depth and, consequently, a deep weld

- Laser welding generates minimal thermal effects and does not easily cause deformation of the metals in the welded area. Additionally, compared to traditional welding, laser welding offers greater strength

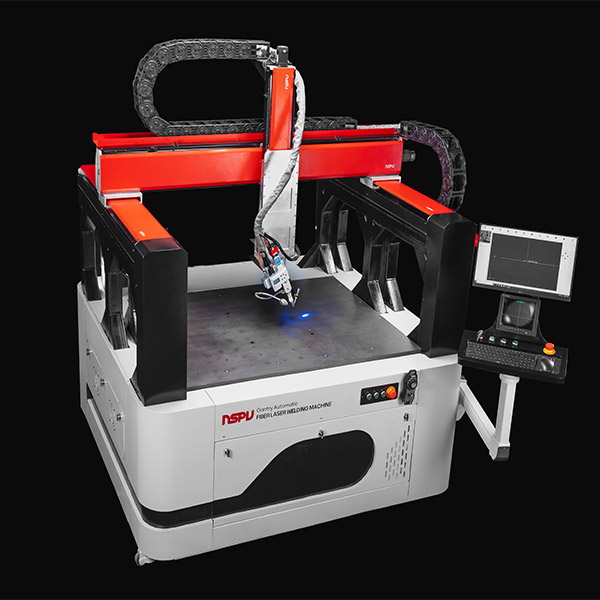

- Customization with Multi-Mode Laser

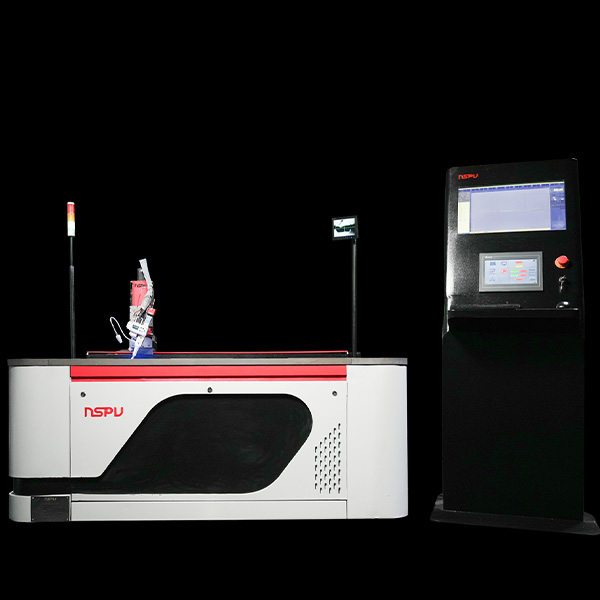

- Customization with Single-Motor Welding Gun

Features of the Laser Welding Machine

- Deep and Narrow Welds: Very clean welds with minimal heat-affected zones

- High Welding Speed: Efficient and quick process

- Lightweight Welding Handpiece: Easy to handle and maneuver

- Six Weld Forms: Selectable options for different welding needs

- Welding of Two Metals Without Filler Materials: Enables direct joining of dissimilar metals

- Joining Metals of the Same and Different Composition: Versatile in application

- No Deformation of Metal Due to Heat: Maintains the integrity of the original material

- High Strength of Welds: Equal to or even greater than the base metal’s strength

- Simple Operation and Quick Learning: User-friendly design for ease of use

- Welding Thin Sheets: Capable of welding sheets thinner than 0.3 mm

- Energy Consumption Reduction: Up to 80% less electricity compared to arc welding

- Welding in Special Conditions: Operable in vacuum electromagnetic fields and in the presence of specific gases under transparent materials

- Clean Welds Without Impurities: Produces high-quality welds

- Ease of Welding Complex and Hard-to-Reach Parts: Suitable for intricate designs

- Price of Handheld Laser Welding Machine: Contact our experts at NSPV for details

Introduction to the Laser Welding Machine

The laser welding machine allows for various welding applications at any angle, including complex welding along seams and edges, creating watertight joints without the need for polishing. Thanks to the machine’s fundamental operation, various metals—including stainless steel, iron sheets, galvanized materials, aluminum, and other metallic substances—can be welded together quickly. This machine serves as an excellent alternative to traditional argon welding and is economically advantageous when working with thin sheets, eliminating the need for additional filler material

Safety features have been prioritized in this device. For instance, the welding switch only activates when the welding handpiece is in contact with the metal, and the light turns off immediately upon removal from the workpiece. Additionally, the handpiece switch is equipped with a body temperature sensor. Compared to arc welding, using this electric welding machine reduces costs by approximately 30%, allowing even ordinary workers to achieve high-quality welding with just a short training period

For more information on pricing and details about the laser welding machine, please contact our experts at NSPV

Technical specifications of laser welding machine

|

VHLW-2000 |

VHLW-1500 |

VHLW-1000 |

Model |

|

2000 w |

1500 w |

1000 w |

Laser Power |

|

Fiber laser 1080 nm |

Laser Wavelength |

||

|

M2 less than 1.3 |

Beam Quality |

||

|

Continuous |

Laser Output Type |

||

|

1-50000 Hz |

Pulse Frequency |

||

|

0 to 100% |

Power Adjustment Capability |

||

|

0.2-5 mm |

Weld Spot Diameter |

||

|

0-120 mm/s |

Average Welding Speed |

||

|

Equipped with Red Light Indicato |

Weld Location Adjustment |

||

|

10m |

Cable Length |

||

|

Water-Cooled Chiller |

Cooling System |

||

|

Dual-Motor Welding Gun (with wobble) Brand QILIN |

Welding Gun |

||

|

Automatic Welding Wire Injection |

Welding Wire Injection System |

||

|

1190*1100*650 |

Machine Dimensions |

||

|

220Kg |

Machine Weight |

||

Based on the tables below, you can select the desired power for your laser welding machine for

various sheets with different thicknesses

|

Weld Depth Specifications and Laser Power |

1000 w |

|

|

Metal Thickness |

Weld Penetration Depth |

Metal Type |

| ≤4mm | ≤2.5mm |

Stainless Steel |

| ≤4mm | ≤2.5mm |

Iron |

| ≤3mm | ≤2mm |

Galvanized |

| ≤2mm | ≤1mm |

Aluminum/Copper |

|

Weld Depth Specifications and Laser Power |

1500 w |

|

|

Metal Thickness |

Weld Penetration Depth |

Metal Type |

| ≤6mm | ≤3.5mm |

Stainless Steel |

| ≤6mm | ≤3.5mm |

Iron |

| ≤5mm | ≤3mm |

Galvanized |

| ≤4mm | ≤2mm |

Aluminum/Copper |

|

Weld Depth Specifications and Laser Power |

2000 w |

|

|

Metal Thickness |

Weld Penetration Depth |

Metal Type |

| ≤8mm | ≤5mm |

Stainless Steel |

| ≤8mm | ≤5mm |

Iron |

| ≤7mm | ≤4mm |

Galvanized |

| ≤6mm | ≤3mm |

Aluminum/Copper |

After-Sales Service and Installation of the Laser Welding Machine

After purchasing the machine, experts from NSPV will be present on-site for the installation. Training on both the software and hardware of the automatic laser welding machine will be provided to the buyer by the experts after installation

How to Place an Order for the Laser Welding Machine

To place an order and purchase the laser welding machine, please contact the numbers listed for Novin Sanat PartoGostar Vanda (NSPV) on our Contact Us page. NSPV is a manufacturer of laser machines and an importer of spare parts for laser welding machines