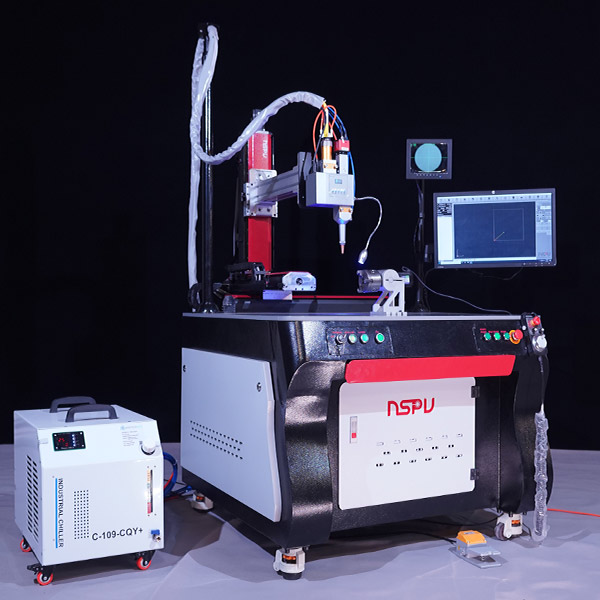

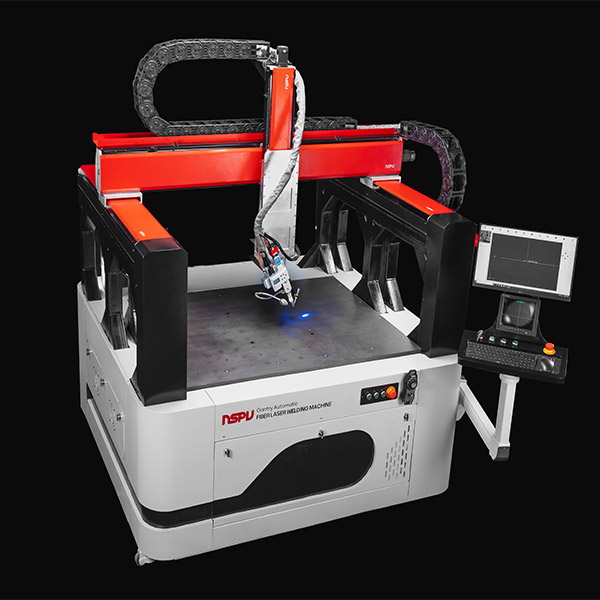

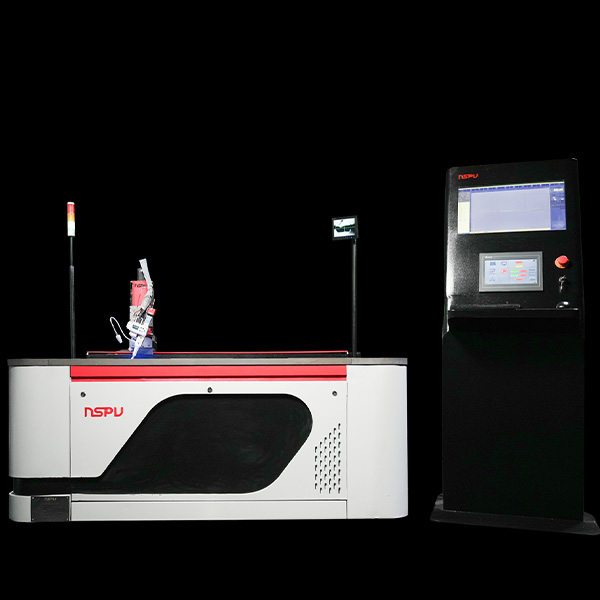

4 axis automatic laser welding machine

ویژگی های محصول

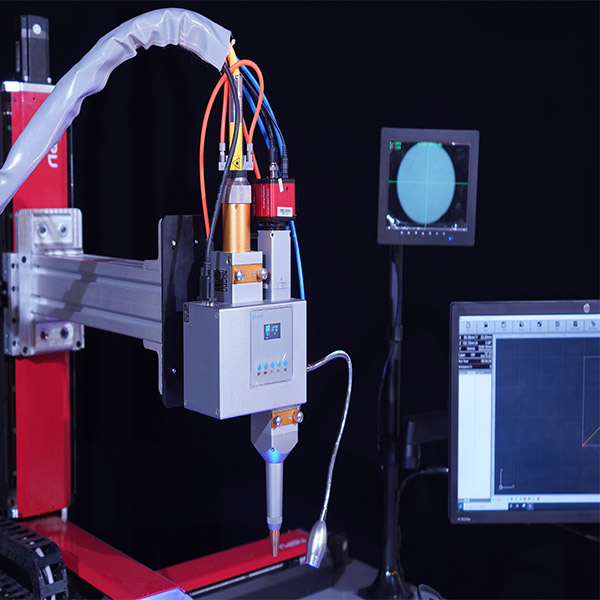

- Real-time Display of Control Values During the Welding Process to monitor and achieve the best welding results.

- Four-Axis Control System for easy programming of precise welding.

- Equipped with a CCD System and Display for real-time monitoring of the process, enabling accurate and delicate welding based on user requirements.

- Robotic Control for Precise Welding in complex and delicate parts that are challenging to perform manually.

- Increased Efficiency of the Welding Process in terms of speed, accuracy, and finesse compared to manual processes.

- Very Clean and Neat Deep and Narrow Welds.

- High Welding Speed.

- Ability to weld Two Metals of the Same Type and Even Different Types.

- Customizable Motion Axes.

Other Features of the Automatic Laser Welding Machine

- No Deformation Due to Heat

- High Weld Strength Equivalent to or Exceeding Base Metal

- Simple Operation and Quick Learning

- Long Lifespan in High-Volume Productions Compared to Traditional Welding

- Welding of Thin Sheets

- Welding of Miniature and Small Parts with High Precision

- Reduction of Electrical Energy Consumption by up to 80% Compared to Traditional Welding

- Clean Weld Without Impurities

- Equipped with 4 to 6 Motion Axes Based on Requirements

- Capability to Upgrade Laser Power Up to 3 kW

- Adjustable Weld Spot Diameter

- Options for Different Weld Shapes

- Equipped with Foot Pedal for Welding Control and Handwheel for Precise Axis Movement

- Protected by an Alarm System

Price of the Automatic Laser Welding Machine

For details and pricing of the automatic laser welding machine, please contact our experts at Vanda (NSPV)

Applications of the Automatic Laser Welding Machine

- Sanitary Industries: Welding of water pipe connections, tees, faucets, and showers

- Automotive Industry: Welding of cylinder head gaskets, hydraulic seals, spark plugs, and filters

- Glass Industry: Welding of steel, stainless steel, and titanium molds

- Electronics Industry: Welding of solid-state relays, batteries, enclosures and motor systems, and fiber optic connectors

- Home Appliances: Welding of kitchen utensils and handles

Technical specifications of automatic laser welding machine

| VALW-4A-3000 | VALW-4A-2000 | VALW-4A-1500 | VALW-4A-1000 |

Model |

| 3000 w | 2000 w | 1500 w | 1000 w |

Laser Power |

| Fiber laser |

Laser Source |

|||

| Fiber laser 1080 nm |

Laser Wavelength |

|||

| M2 Less than 1.3 |

Beam Quality |

|||

| Continuous |

Laser Mode |

|||

| 1-50000 Hz |

Pulse Frequency |

|||

| 0 to 100% |

Power Adjustment Capability |

|||

| 0.2-5 mm |

Weld Spot Diameter |

|||

| 200/300 mm |

Focal Distance |

|||

| Equipped with Red Light Indicator |

Weld Location Adjustment |

|||

| Viewing the welding site through a camera |

Weld Location Display |

|||

| Water-Cooled Chiller |

Cooling System |

|||

| Dual-Motor Wobble Welding Head Brand QILIN |

Welding Head |

|||

| Up to 150mm/s |

Average Welding Speed |

|||

| ±0.01 mm |

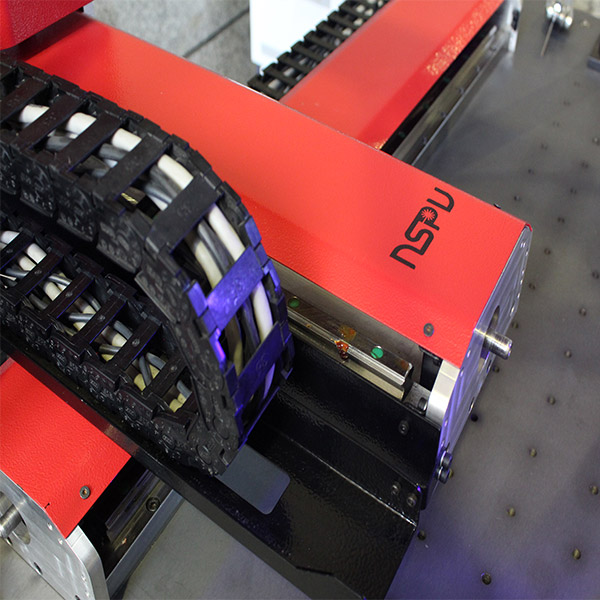

Positioning Accuracy on Axes |

|||

| (X=500mm , Y= 400 mm , Z= 300mm) |

Linear Motion Axes |

|||

| A=±360° |

Rotational Motion Axes |

|||

|

8kw |

7kw |

5.5kw |

4kw |

Power Consumption |

|

AC 360 |

AC 360 V |

AC 220V 50/60 Hz |

Power Supply |

|

Introduction to the Automatic Laser Welding Machine

With the continuous advancement of laser technology, the production of machines and equipment that utilize this technology has expanded. One of these machines is the laser welding machine. The high density of laser light can heat the surface to its boiling point within a few milliseconds, resulting in vaporization. This phenomenon is suitable for processes such as laser drilling and laser cutting. For lower laser powers, the surface temperature reaches the boiling point after a few milliseconds. Before vaporization occurs, the temperature of the underlying layers reaches the melting point, which allows for good laser welding between surfaces.

By combining the laser welding machine with a CNC system and transforming a manual laser welding machine into an automatic laser welding machine, it becomes easy to weld parts that require intricate and precise welding, which is difficult to achieve with manual laser welding.

After-Sales Service and Installation of the Automatic Laser Welding Machine

After purchasing the machine, experts from NSPV will be present on-site for the installation. Software and hardware training on the automatic laser welding machine will be provided to the buyer by the experts after the installation.