Laser cleaning machine

Laser cleaning machine

ویژگی های محصول

- Contactless cleaning with the surface

- Cleaning without consumables and solely using electricity

- Cost reduction of up to 84% compared to dry ice cleaning

- No damage to the surface during cleaning

- Free maintenance

- Quick setup and simple operation

- Various cleaning modes (spiral, uniform, etc.)

- High cleaning efficiency and time-saving

- Reduced sensitivity to corrosion after cleaning

- Robotic cleaning capability

- Environmentally friendly, without the use of chemicals or solvents

- Low noise

- Uniform cleaning with the ability to select and control the cleaning area

Technical specifications of laser cleaning machine

| LCI-2000 |

LCI-1500 |

LCI-1000 |

Model |

| 2000w | 1500w | 1000w | Laser Power |

| 7 kw | 5.5 kw | 4 kw | Power Consumption |

| fiber laser 1080 | Laser Wavelength | ||

| Less than 1.3 | Beam Quality | ||

| Fiber | Laser Source | ||

| Continuous | Laser Output Type | ||

| 1-4000 Hz | Pulse Frequency | ||

| 0.15-50 ms | Pulse Width | ||

| 0 to 100% | Power Adjustability | ||

| Red light indicator | Cleaning Position Adjustment | ||

| 10 meters | Cable Length | ||

| Linear scan and Spiral scan | Cleaning Head | ||

| Water-cooled chiller | Cooling System | ||

| 1100mm*990mm*650mm | Device Dimensions | ||

| 220KG | Device Weight | ||

Removing rust from metal surfaces, removing surface paint and oil, cleaning stains, mud and grime on parts, cleaning rubber and plastic production molds

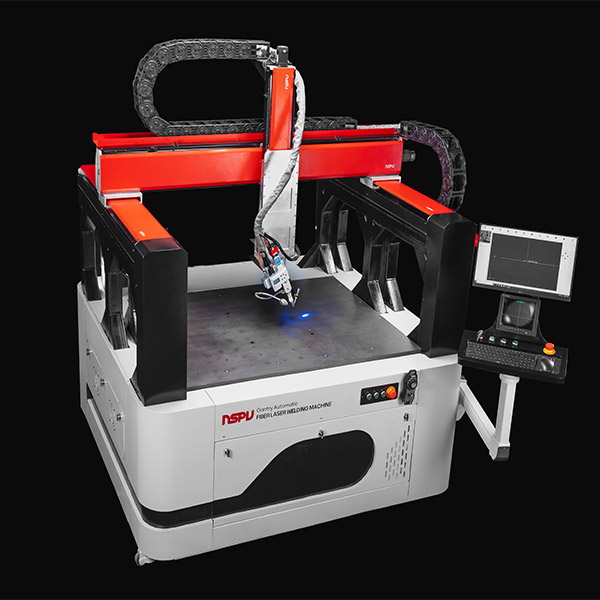

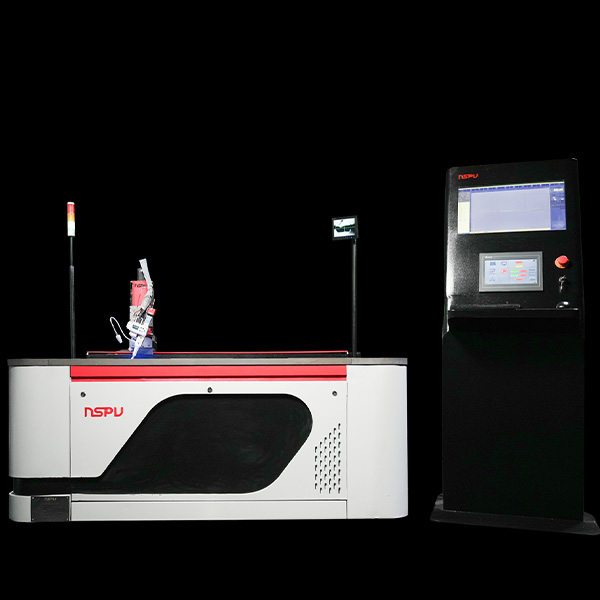

Introduction to Laser Cleaning Devices

Lasers can perform cleaning and surface preparation at high speeds in almost all industries. With the use of a laser cleaning device, maintenance processes that involve the removal of oil, grease, paint, or coatings can be done easily and automatically. No abrasive materials are used in this process, and there is no issue with disposing of pollutants. Moreover, no chemical solvents are utilized, making the entire process environmentally friendly. Another advantage of this laser cleaning device is that only the necessary area can be cleaned, saving both time and costs.

Due to the non-contact nature of the cleaning process, surface quality is not compromised, and this technology allows for the entire maintenance process to be carried out automatically. As a result, operational costs are reduced by eliminating labor while simultaneously increasing the quality of work execution.

After-Sales Services and Installation of the Laser Cleaning Device

After purchasing the device, experts from Novin Sanat Parto Gostar Vanda will be present on-site for installation. Training on both software and hardware related to the laser cleaning device will be provided to the buyer after the installation is complete.

How to Place an Order for the Laser Cleaning Device

To place an order and purchase the laser cleaning device, please contact Novin Sanat Parto Gostar Vanda using the phone numbers provided on our Contact Us page